How to Improve Inventory Management?

Having given you a few tips on how to reduce delivery times and put the spotlight on 4PL logistics, let’s now turn our attention to inventory management. How can we improve it on a daily basis? How can it be optimized without costing too much time and money? Here are our tips and tricks to help you do just that

Why is it important to optimize inventory management?

Just as a good reverse logistics strategy is crucial to improving a company’s attractiveness, inventory management is an important factor in raising the profile of your business, building loyalty and attracting more customers. And there are many reasons for this. Good inventory management makes it possible to :

- Better visibility of the supply chain;

- Avoid under-stocking to avoid lost sales;

- Minimize overstocking to save money spent unnecessarily;

- Minimize losses due to inventory errors;

- Improve servicequality and, by extension, customer satisfaction through compliant products and faster delivery.

All these concepts, which are an integral part of fulfillment, are bound to have been on your mind at one time or another. All you needed to do was find the right inventory management method for your business

Improving inventory management: the available methods

Whatever your business, there’s bound to be a solution adapted to your inventory management among the following 8 methods:

1/ FIFO (First In First Out) method:

Items are sold in the order of arrival, i.e. the first items in stock are the first to be dispatched. This inventory management method is mainly used for perishable products or products with an expiration date.

2/ LIFO (Last In First Out) method:

Last in, first out. Products sold are the last to be put into stock. This method is often used for non-perishable products.

3/ Continuous replenishment method:

This involves replenishing stock as soon as it reaches a predetermined minimum level. This technique is frequently used for fast-moving products.

4/ Just-in-time method:

Order and produce only what you need for each stage of production or distribution. Your stock will be limited, and you’ll only buy the products your customers want. However, you need to be careful with this type of inventory management: your supplier needs to be reactive in order to respond as quickly as possible to consumer expectations.

5/ Demand forecasting method:

Manage inventory according to upcoming trends and the shopping season – Sales, Black Friday, Christmas, etc. – to anticipate higher or lower sales volumes. It’s important to understand your sales seasonality.

6/ MRP (Material Requirements Planning) method:

Inventory planning based on the need for raw materials, components and finished products to meet customer demand. This method uses sales forecasts and production lead times to calculate the supply requirements needed to produce finished products.

7/ ABC method (Activity Based Costing) :

Allows products to be classified according to their value to the company, and management efforts to be concentrated on the most important, most in-demand and most profitable references.

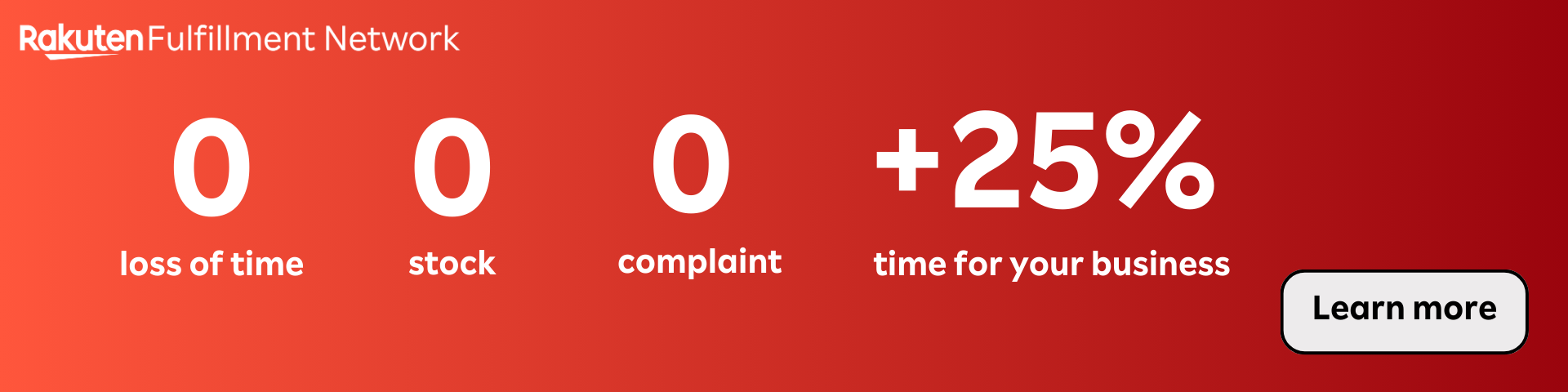

8/ Outsourcing logistics :

What if the key to good inventory management lay in outsourcing your logistics? Storage and management of orders, packaging and delivery of parcels, after-sales service… The benefits of outsourcing are numerous, provided you choose the right logistics provider.